YINI I-Induction Harding?

Yini i-Induction Harding?

Ukuqina kokungeniswa kuyindlela yokucisha esebenzisa umgomo wokungeniswa kuka-electromagnetic ukwenza ucezu lomsebenzi lusike imigqa yakazibuthe endaweni eshintshanayo yakazibuthe futhi ikhiqize amandla akhona endaweni yezingxenye zensimbi. Ngokomphumela wesikhumba we-alternating current, indawo engaphezulu yengxenye eshisayo ishisa ngokushesha ngendlela ye-eddy current bese i-induction ivala ngokushesha.

Ngemva kokuba umshini wokufudumeza lokungeniswa iqeda inqubo yokushisa nokucisha, izingxenye zensimbi ubulukhuni bobuso buphezulu, umnyombo ugcina ipulasitiki enhle nokuqina, ubonisa ukuzwela okuphansi, ngakho-ke ukuqina komthelela, amandla okukhathala, nokumelana nokugqoka kuthuthukiswa kakhulu. Ngenxa yesikhathi esifushane sokushisisa, i-oxidation engaphezulu, kanye nokukhishwa kwe-carburization kwezingxenye kancane, uma kuqhathaniswa nezinye izindlela zokwelapha ukushisa, izinga lokwenqatshwa kwezingxenye liphansi kakhulu. Futhi ukukhetha i-coil yokushisa yokungenisa efanelekile kudlala indima ebalulekile emkhakheni wokwelashwa kokushisa kwensimbi.

Kungani usebenzise inqubo yokufaka ukuqina kwe-induction?

I-induction quenching yinqubo lapho ama-eddy currents enziwa khona endaweni yokusebenza yensimbi ngokungeniswa kwe-electromagnetic futhi ucezu lokusebenza luyashiswa. Uma kuqhathaniswa nobuchwepheshe bokushisa obujwayelekile bensimbi, ubuchwepheshe bokucisha induction bunezinzuzo ezilandelayo:

1. Ukuqina kwendawo yokusebenza kwensimbi kuphezulu. Ukuqina kobuso bomsebenzi oqiniswe ukushisisa kwe-induction imvamisa ephezulu naphakathi buyi-2 ~ 3 HRC ephakeme kunaleyo yokucisha okuvamile. Ukuqina kwayo komthelela wensimbi, amandla okukhathala, nokumelana nokugqoka kuba ngcono kakhulu. Impilo yesevisi ye-workpiece yensimbi inganwetshwa kakhulu ngokucisha induction.

2. I-workpiece yensimbi ayikona ukushisa okuhlangene, ngakho-ke ngokuqiniswa kwe-induction, i-workpiece yonke i-deformation incane;

3. Isikhathi sokushisa sensimbi sifushane, inani le-surface oxidation decarburization lincane;

4. Umthombo wokushisa usebenza endaweni yokusebenza yensimbi, isivinini sokushisa nokusebenza kahle kuphezulu;

5. Isakhiwo semishini yokucisha i-induction sihlangene kakhulu kunemishini yokushisa yensimbi evamile, kulula ukuyisebenzisa.

6. Umshini wokuqinisa induction uqaphela ukucutshungulwa kokwelashwa kokushisa okungomshini nokuzenzakalelayo, konga izindleko zabasebenzi.

7. Ubuchwepheshe bokwenza ukuqina kwe-induction ekuqiniseni indawo bungasetshenziswa futhi ekushiseni kokungena kanye nokwelashwa kokushisa kwamakhemikhali.

Ungayikhetha kanjani inqubo yokufaka ukuqina kwe-induction efanele?

Inqubo yokufaka ukuqina kwe-induction inezindlela ezimbalwa zokufudumeza futhi zonke zinezindawo zokusebenza ezifanele zokufudumeza.

1. Indlela yokuqinisa ukushisisa kwe-induction yesikhathi esisodwa:

Ukushisa kokungeniswa kwesikhathi esisodwa noma ukushisisa kokungeniswa kanyekanye kuyindlela evame kakhulu yokwenza lukhuni yokungeniswa. Uma le ndlela isebenzisa amashubhu amabili angunxande azungeze indawo yokusebenza ukuze kufudumale ngokujikelezayo, ngokuvamile ibizwa ngokuthi i-Single Shot.

Inzuzo yale ndlela yokushisisa i-induction ukuqedela yonke imisebenzi yokushisisa indawo yokusebenzela ngesikhathi esisodwa. Ngakho-ke, ukusebenza kwayo kulula, ukukhiqiza kuphezulu, kufanelekile ukushisa indawo yokusebenzela akuyona enkulu kakhulu. Ukuze ushise i-workpiece yendawo enkulu, sebenzisa indlela yokushisa yesikhathi esisodwa, idinga amandla amakhulu kanye nezindleko eziphezulu zokutshala izimali.

Izibonelo ezivame kakhulu zokuqina kokushisa kokungeniswa kwesikhathi esisodwa amagiya e-modulus amancane naphakathi, amagobolondo egobolondo amise okwensimbi eyi-CVJ, imigwaqo yangaphakathi, amasondo enkampani yenethiwekhi, amasondo asekelayo, izikhonkwane zesiphethu seqabunga, izidonsa, iziphetho ze-valve, ama-valve rocker arm arcs, njll.

2. Iskena indlela yokuqinisa induction:

Lapho indawo yokushisa i-workpiece inkulu, ukunikezwa kwamandla okushisa kwe-induction kuncane, le ndlela ivame ukusetshenziswa. Kuleli qophelo, indawo yokushisa ebaliwe S ibhekisela esifundeni esiqukethwe indandatho yokungeniswa. Ngakho-ke, ukuminyana kwamandla okufanayo, i umshini wokufudumeza lokungeniswa amandla adingekayo mancane, ukuncintisana umshini wokuqina wokufakelwa izindleko zokutshala imali ziphansi, zilungele ukukhiqizwa kokuqina kwe-batch induction, izibonelo ezijwayelekile induku yepiston enobubanzi obukhulu, i-corrugated roll, roll, ipayipi likawoyela, i-sucker rod, ujantshi, isitimela somhlahlandlela wamathuluzi omshini nokunye.

3. Isigatshana indlela yokucisha ukushisa kokungeniswa kwesikhathi esisodwa

Izibonelo ezijwayelekile ukuqiniswa kwama-camshaft amaningi, isikhathi ngasinye lapho kushisa ikhamera eyodwa noma ngaphezulu, ngemuva kokuqeda lesi sikhathi sokucisha, ukushisa enye ingxenye ye-cam, amagiya aqiniswe izinyo ngezinyo nawo angafakwa kulesi sigaba.

4. Indlela yokuqeda ukuskena kokungeniswa kwesigatshana

Izibonelo ezijwayelekile ama-valve rocker shafts noma ukuqina kokufakwa kwe-valve shafts eshintshashintshayo, lapho izingxenye eziningi ze-shaft ziskenwa ukuze kucishwe i-induction, ububanzi bokucisha bungase buhluke, futhi ukucishwa kokuskena kwezinyo kungase kufakwe kulesi sigaba.

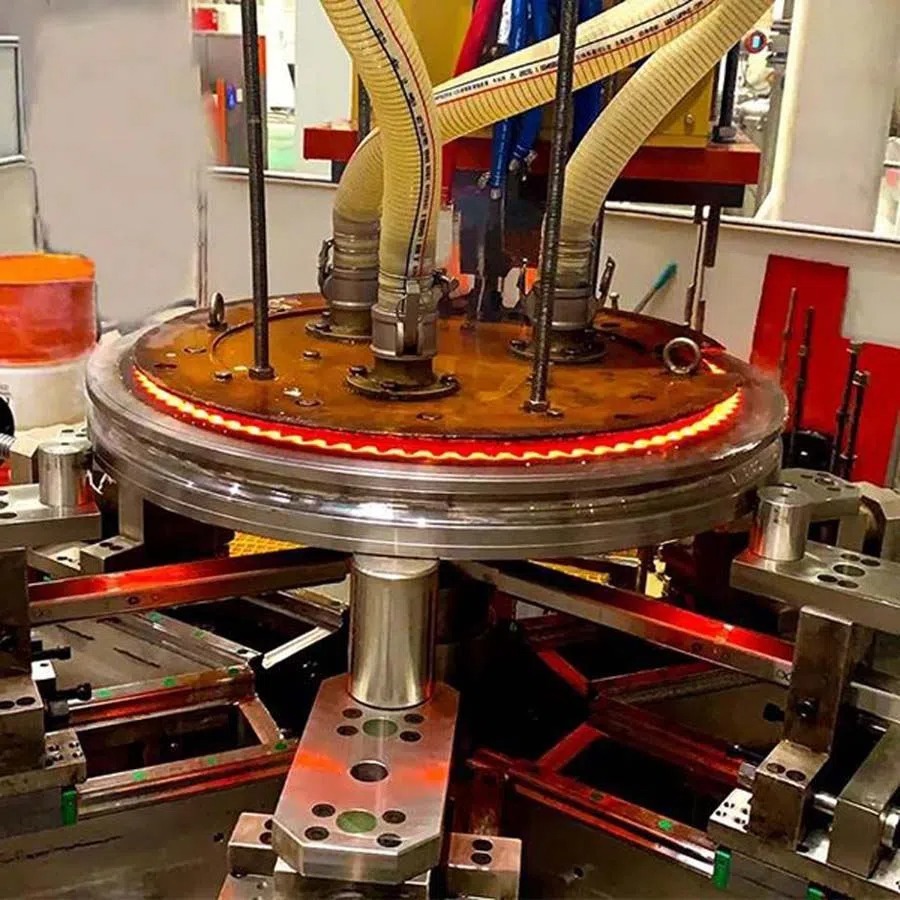

5. Ukushisa kokungeniswa kanye nokucisha oketshezini

Induction ukuqina quenching oketshezini, kusho coil induction futhi indawo yokushisa yocwecwe bokusebenza icwiliswa oketshezini lokucisha lokungeniswa, olushisiwe, ngenxa yokuminyana kwamandla angaphezulu kwendawo yokushisisa kuba kukhulu kunezinga elizungezile lokupholisa uketshezi lokucisha. Ngakho-ke, ubuso bushisa ngokushesha. Lapho i-inductor ivaliwe, ingaphezulu le-workpiece liyaqina ngenxa yokumuncwa ukushisa kwengqikithi ye-workpiece kanye nokupholisa uketshezi olucishayo.

Le ndlela ngokuvamile ifanelekela ucezu lwensimbi oludinga izinga lokupholisa elibucayi kakhulu. Lapho i-workpiece ibekwe emoyeni futhi ikhoyili yokungeniswa ivaliwe, ukushisa kwendawo kudonswa phakathi nendawo yokusebenza. Lapho izinga lokupholisa lendawo eshisayo likhulu kunezinga lokupholisa elibalulekile, umsebenzi wokusebenzela uqiniswa, okufana nokucisha oketshezini.

Yiziphi izingxenye zesistimu yokuqinisa i-induction?

Ukwakheka okuphelele umshini wokuqeda ukukhipha ngokuvamile kufaka phakathi ukunikezwa kwamandla okushisa okufakwayo, ithuluzi lomshini wokwenza lukhuni we-CNC, ikhoyili yokufaka ukuqina, kanye nohlelo lokujikeleza kwamanzi okupholisa olusizayo kanye nohlelo lokujikeleza koketshezi lokucisha.

Abakhiqizi bemishini yokushisa yokungeniswa yesimanje, ingxenye enkulu yekhono lokwenza amasethi aphelele emishini yokuqinisa yokungeniswa kanye nephrojekthi ye-turnkey, umsebenzisi ukuze afinyeze umjikelezo wokukhiqiza, futhi agwenywe ngenxa yomnyango wokuhlinzeka ngenqwaba yenqubo yokulungisa iphutha ayihambisani, kanye nezinkinga ezinde zokulungisa iphutha njengesikhathi. Ukuhlinzekwa kwemishini ephelele kanye namaphrojekthi we-turnkey sekuyindlela yokuncintisana yabakhiqizi bemishini.

Sekukonke, Njengomunye wabakhiqizi abahamba phambili besistimu yokufaka ukuqina kwe-induction e-China, sisize izinkulungwane zezimboni zokwelapha ukushisa ukuze zithole izixazululo ezifanele zokwelapha ukushisa kokungeniswa kakade, ngakho-ke ukuze siqiniseke ukuthi inqubo yokufaka ukuqina kwe-induction system efanele. Ngicela ungivumele ngibe nemidwebo yezingxenye zakho eziqinisayo, izinto ezibonakalayo, ubulukhuni, kanye nezicelo zokujula eziqinisayo, futhi singakunikeza iziphakamiso zobuchwepheshe ezihambisanayo zokuqinisa ukushisisa kwesistimu kanye namashidi ekhotheshini. Ngiyabonga.

I-Induction Ukuqina Kwesistimu Amacala Okufaka Isicelo Sengxenye

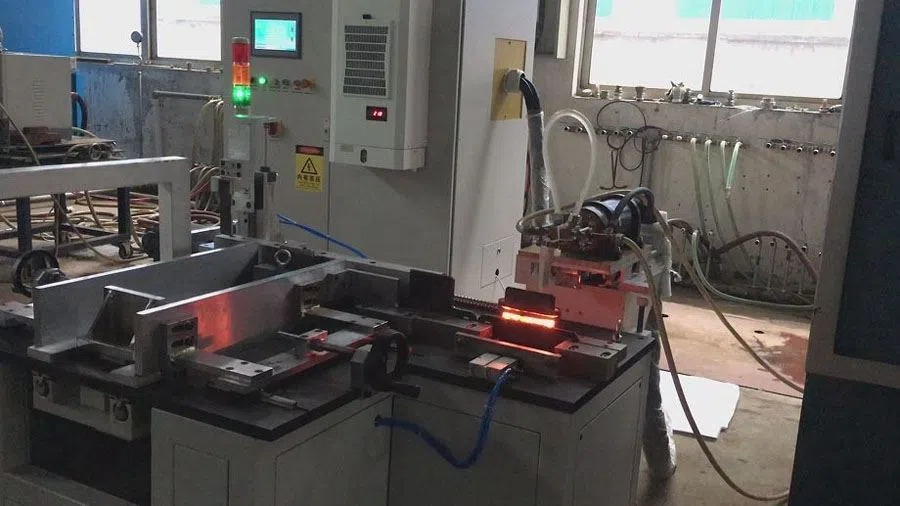

1. Umzila womjaho oqondile oqondile we-CNC uhlelo lokucisha umshini

2. Uhlelo Lokuqinisa I-Chain Plate Induction

3. Cantilever igiya CNC induction ukuqina uhlelo umshini

4. I-Wind Power Bolt Induction yokucisha kanye ne-Tempering System Production Line

5. Igobolondo le-shaft elilinganiselwe igobolondo langaphakathi le-induction system yokuqinisa ukushisa

6. I-Large Mill Roller Induction Hardening